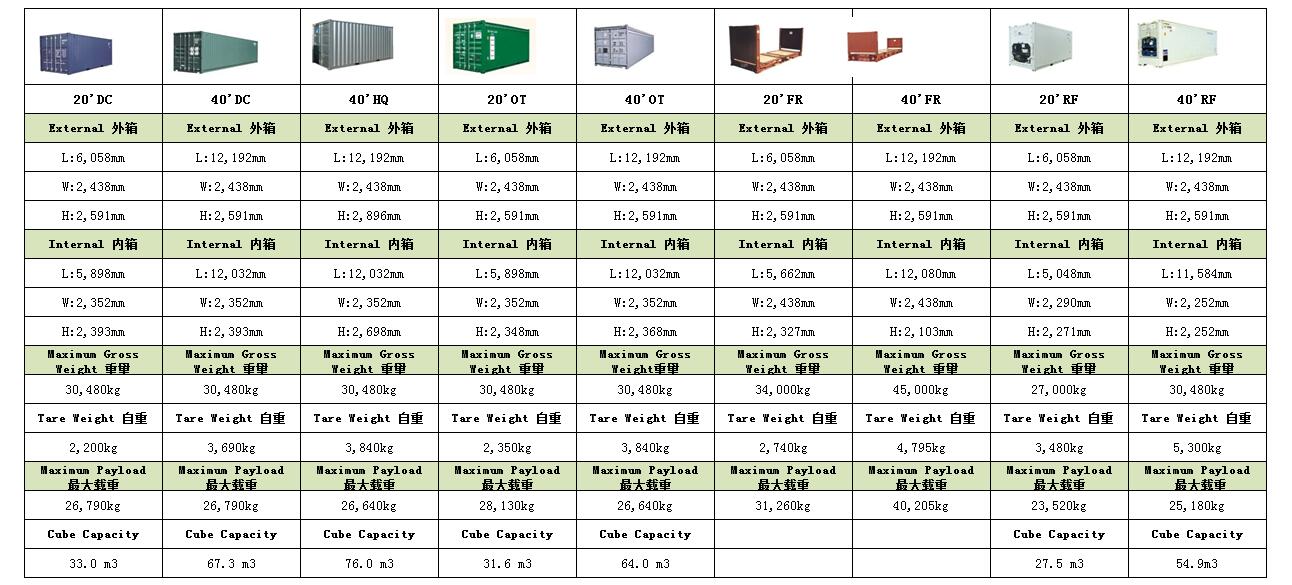

1.Container Specifications

2.Regulations on Container Stuffing Operation

Chapter I General Provisions

Article I

The Regulations are formulated for the purposes of standardizing container stuffing operation, guaranteeing safe transport of containers and protecting the rights and interests of both Company and shippers.

Article II

The staffs of agency companies should actively introduce and explain to container users that their container stuffing operation should comply with the regulations on container stuffing operation. For any question, they should timely explain to container users and report the trade lane operation department and Equipment Control Center of Headquarter. Any violation in container stuffing is prohibited..

Article III

If the agency company is fully aware the user’s inconformity of container stuffing but still accepts the booking, such agency company should be held jointly and severally liable for any loss resulting therefrom.

Article IV

If the container user acquires booking confirmation by treating or fraud against agency company, it should be held solely liable for any loss caused by inconformity with the container stuffing regulations.

Chapter II Rules for General Cargo Stuffing Operation

Article V

The planned stuffing weight should not exceed the allowable max payload of container. After stuffing, the total weight of container should not exceed the max gross weight stated on the consolidated data plate, and comply with the limits of total weight on the intended trade lanes. The nameplate lies on the container closure doors and for the special-purpose container with no closure door it is generally on the rear corner post or bottom beam.

Article VI

When stuffing, the load on bottom of container must be balanced where load on one end or side should be avoided especially the goods gravity deviation to one end strictly prohibited. Excessive load concentration should be avoided. If heavy goods are loaded such as machinery equipment, stone, steel coils, wood or foundation, straw mattress dedicated for steel coils or other similar cushion materials in compliance with the legal requirements at the locations of both consignor and consignee like scrap tire, rubber mattress, etc. should be placed at the bottom of goods to scatter load as far as possible.

60% or above weight of goods should not be loaded within half of the container length.

The heavy goods with unit weight over 3 tons such as steel coils should be stuffed on pallet or wooden dunnage that ensure safe transport, which should also be properly lashed and secured.

Article VII

The stuffing instruments should be correctly used and dragging should be avoided when manual or forklift stuffing is used. The forklift for handling heavy goods like steel coils must be compatible for suspended folk-in and out and dragging is prohibited, e.g. 10t steel coils must be handled by the forklift with minimum workload of 10t so as to avoid dragging damage of goods and floor.

Article VIII

Handling by forklift is restricted by free lift height, door height, etc. Where conditions permit, the forklift may stack two s at a time but with around 20mm overhead clearance and around 100mm bottom clearance. Where stacking of two s at a time is not permitted by conditions, for the upper , the free lift height of forklift and possible elevation height of forklift mast should be considered to avoid damage to container ceiling. In addition, whether there are pallet or fork pockets under goods should be noted and wood dunnage must be added so that the forks can be smoothly withdrawn to avoid damage to goods and floor. The rated lift weight of forklifts operating within containers should be not more than 2.5 tons.

Article IX

When different types of goods are mix loaded, the following points should be noted:

i. Heavy goods should be loaded beneath light goods and solid goods not to be loaded beneath liquid goods.

ii. The goods with weaker packing strength should be placed above the goods with stronger packing strength.

iii. Goods of different shapes and packing should not be put together as far as possible.

iv. The goods with possible leakage of dust, liquid, humidity, odor, etc. from packing should not be loaded together with other goods as far as possible. If mix loading is unavoidable, such goods should be completely separated by canvas, plastic membrane or other cushion materials, and the floor should also be covered with cushion materials to prevent irremovable damage. Floor replacement may cost unnecessary loss high up to millions of dollars.

v. The goods with sharp angles or other projections should be shrouded to prevent damage to other goods and container.

Article X

After completion of stuffing, goods should be reasonably lashed and secured to prevent movement, which may sway during transport and cause damage to goods and container. In the meantime, the securing means should not cause damage or deterioration of goods or container.

Article XI

Stuffing of reefer goods and dangerous goods should be in strict conformity with the relevant loading requirements.

Article XII

For either empty or laden containers, handling by forklift outside the forklift pockets must be prohibited. All handling operations should be in strict conformity with the ISO container handling requirements.

Chapter III Rules for Stuffing of Reefer Containers

Article XIII

The reefer container is de facto thermal insulation container. Hence the frozen goods are quickly frozen to the required temperature and stuffed into the container. The chilled goods should also be properly pre-cooled to avoid impact on reefer effect due to goods respiratory heat, frosting, etc.

Article XIV

In stuffing, the machine should be stopped to prevent excessive condensation that may hamper operation of evaporator.

Article XV

The wood dunnage and other cushion materials inside reefer containers should also be properly pre-cooled before stuffing.

Article XVI

Clean and sanitary cushion materials should be selected to avoid contamination of goods. Cushion materials like paper or cardboard should not be used to avoid blockage of ventilation pipes and outlets.

Article XVII

Correct stuffing means should be selected in line with property of goods and shapes of packing. In stuffing, it should be noted the ventilation openings must not be blocked by goods and proper overhead clearance should be maintained for valid air circulation. The alarm lines should not be exceeded.

Article XVIII

It should be noted the reefer goods are more slippery and easily damaged than general goods and thus should be well secured. The cushion materials like mesh nets are preferably used in securing, which do not hamper recycling and circulation of cold air.

Article XIX

The goods with reduced freshness or deteriorating goods with smelly odor should not be stuffed in containers, which probably damage other goods quickly.

Article XX

The trucks for haulage of reefer containers should be equipped with 380/440V generators. In pickup the container conditions should be noted and supplied with power so as to ensure the exit of compliant containers from yards.

Article XXI

After stuffing, the continuous power supply to the reefer containers should be maintained to guarantee the required temperature in containers. When problems of container or malfunction occur, the original pickup yard or local equipment control agency should be immediately contacted.

Chapter IV Rules for Stuffing of Dangerous Goods Containers

Article XXII

The stuffing operation and transport of dangerous goods carried by sea should comply with the relevant rules and regulations such as IMO’s International Maritime Dangerous Goods Rule and Safety Specification for the Packing of Dangerous Cargo into Container by Marine Transport.

Article XXIII

The packing of dangerous goods carried by sea should pass the recognized national professional testing and survey organizations with corresponding conformity certification. The code of packing showing conformity of testing and survey should be demonstrated as required.

Article XXIV

The packing symbols of domestic dangerous goods carried by sea should comply with the relevant provisions in GB190.

The packing symbols of international dangerous goods carried by sea should comply with the relevant provisions in IMO’s International Maritime Dangerous Goods Code.

Article XXV

The property, treatment methods, emergency measures, etc. of dangerous goods should be fully understood before container stuffing.

Article XXVI

Stuffing should be carried out in the places with no direct sunlight, no heat or ignition source but good ventilation. Such stuffing place must have adequate space and necessary equipment.

Article XXVII

Before stuffing, the strength and structure of containers should be carefully examined and any container not in compliance with the requirements on dangerous goods should not be used. During stuffing the operators should wear work suits and personal protection equipment like mask or rubber gloves as required, and take shower and cleaning immediately after stuffing operation. No eating or drinking is allowed during stuffing.

Article XXVIII

In stuffing, the containers should be carefully cleaned inside. It should be noted the contact of some explosives and oxidants with the residues inside the containers such as garbage may cause fire, explosion or other hazards.

Article XXIX

The integrity of the vessels, packages and symbols of goods to be stuffed should be carefully examined to see the consistency with the transport documents. The dangerous goods with damaged packing or leaked vessels should be prohibited from stuffing in containers.

Article XXX

For the loading and securing of dangerous goods, in accordance with the shapes of packing, they may be loaded as general cargo but the devices and materials selected to secure such goods should have higher safety coefficient and strength.

rticle XXXI

No part of dangerous goods should extend outside containers and after stuffing, the closure doors must be completely closed.

Article XXXII

The compressed, liquefied or pressurized dissolved gas dangerous goods may be longitudinally or transversely stuffed in accordance with the shape of vessel. When transversely stuffed, adequate cushions should be inserted between goods so as to avoid direct contact of l parts of vessels. The tube-shaped pressure cylinders are in principle stuffed longitudinally, protected by barriers of cushion materials, and tightened and secured by steel ropes.

Article XXXIII

When contact with water, a few dangerous goods packed in paper bags, fiber boxes and fiber cans may have chemical reaction and some may give out heat, self-combustion or toxic gas. Therefore strict watertight inspection is necessary. It should be peculiarly noted the goods stuffed in containers cannot be examined during transport and thus the bad stuffing or damage of vessel inside containers may not be immediately detected. Moreover, in case of incidents their immobility may expand the scope of incidents. These peculiar conditions are totally different from those of dangerous goods carried by general cargo ships.

Article XXXIV

In general it is not required that dangerous goods cannot be mixed with general cargo on the same container ship.

Before stuffing, a loading plan must be developed with consideration to the compatibility and properties of different goods, i.e. any packing or the types or strength of involved packages, as well as the possibility of cross contamination of cargo odor and dust and their physical or chemical compatibility.

The goods with incompatible property of hazard should not be stuffed in one container. If certain goods have single secondary hazard nature but the requirements on such secondary hazard are stricter than their primary hazard, the isolation in compliance with the requirements on secondary hazard should be adopted.

For isolation of stuffed goods inside the container, such isolation should comply with the strictest requirements of these dangerous goods. The reviewer of stuffing should check all the isolation lists in the dangerous goods code with focus on the isolation requirements in the list.

Article XXXV

When both dangerous cargo and general cargo are stuffed, the dangerous cargo should be stuffed later but unstuffed first and be at the place close to the door that can be easily unloaded.

Article XXXVI

Mixed stowage of dangerous goods and food should be prohibited.

Article XXXVII

Goods should be handled gently and carriage on should or back, strike, collision or rolling should be prohibited to prevent damage to packing. If damage or leakage of packing of dangerous goods occurs during handling process, such goods should be immediately and effectively treated under the supervision of stuffing surveyors. If the leaked dangerous goods may cause explosion, self-combustion, poison or any other similar major hazards, all persons should be evacuated to a safe place and the relevant contingency reaction departments should be notified.

Article XXXVIII

The entities engaged in stuffing operation of dangerous goods carried by sea should faithfully record every stuffing operation of dangerous goods including stowage plan, stuffing time, conditions of goods, conditions of container, conditions of packing, stuffing cushion, securing, etc. The stuffing should be recorded by the on-site surveyor in charge of stuffing. Photos of stuffing of dangerous goods should be taken and archived.

For dangerous goods carried in containers, the Container Stuffing Certification issued by stuffing surveyor should be submitted.